What We Do

Expertly

Crafted—

Every Time.

Count on us to bring the structure—delivering quality steel, precision, and expert craftsmanship in

every detail. We take pride in transforming steel into enduring solutions that stand the test of time.

Our Steel Selection

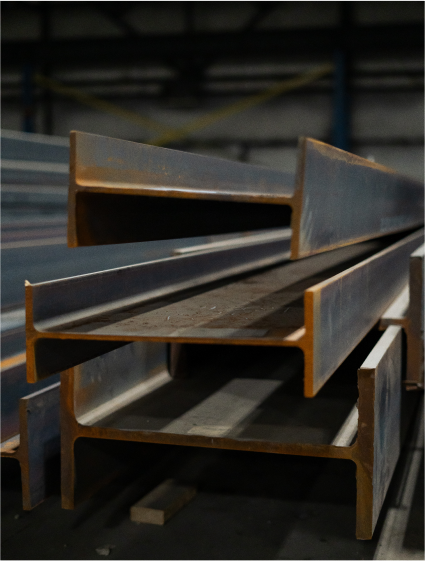

Structural Steel

Structural steel forms a building’s backbone, delivering strength, flexibility, and sustainability. Trusted for its ability to enable creative and innovative designs, it empowers us to push boundaries while maintaining structural integrity.

Our tailored processes and decades of experience provide the structure needed to confidently meet the unique needs of any project.

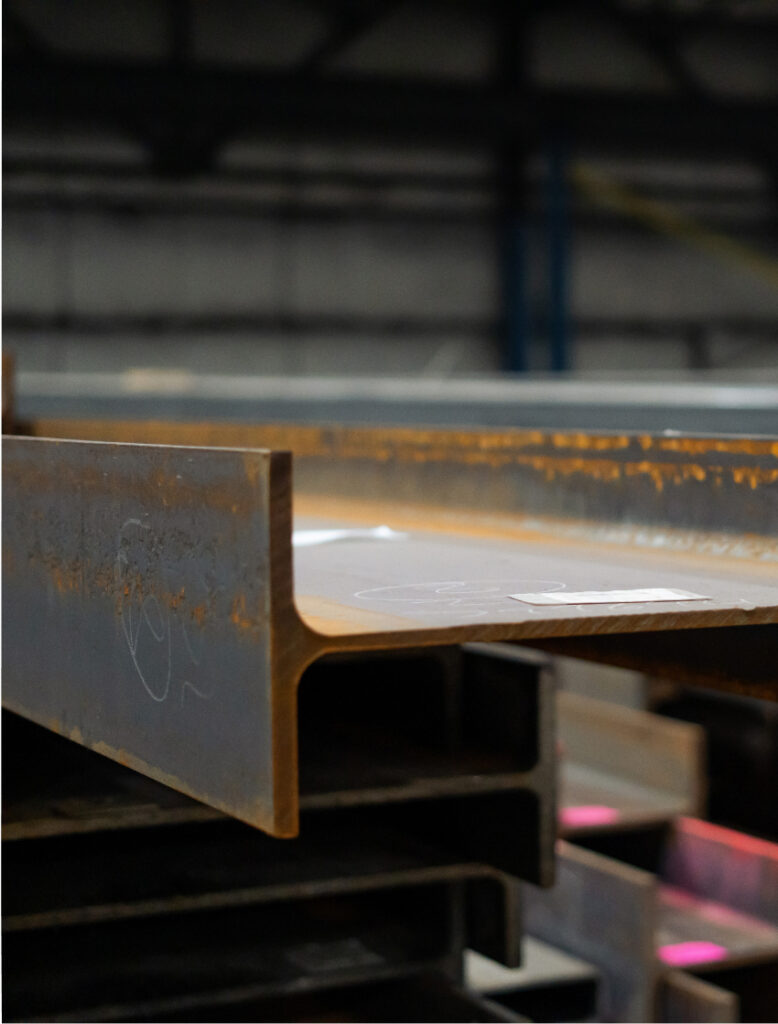

Heavy Steel

Heavy steel is essential for high-rises, bridges, and pipelines, requiring precision and expertise. We Specialize in custom-fabricated columns, trusses, box girders, and built up beams designed to meet your project’s exact needs. Our focus on quality ensures reliable results every time.

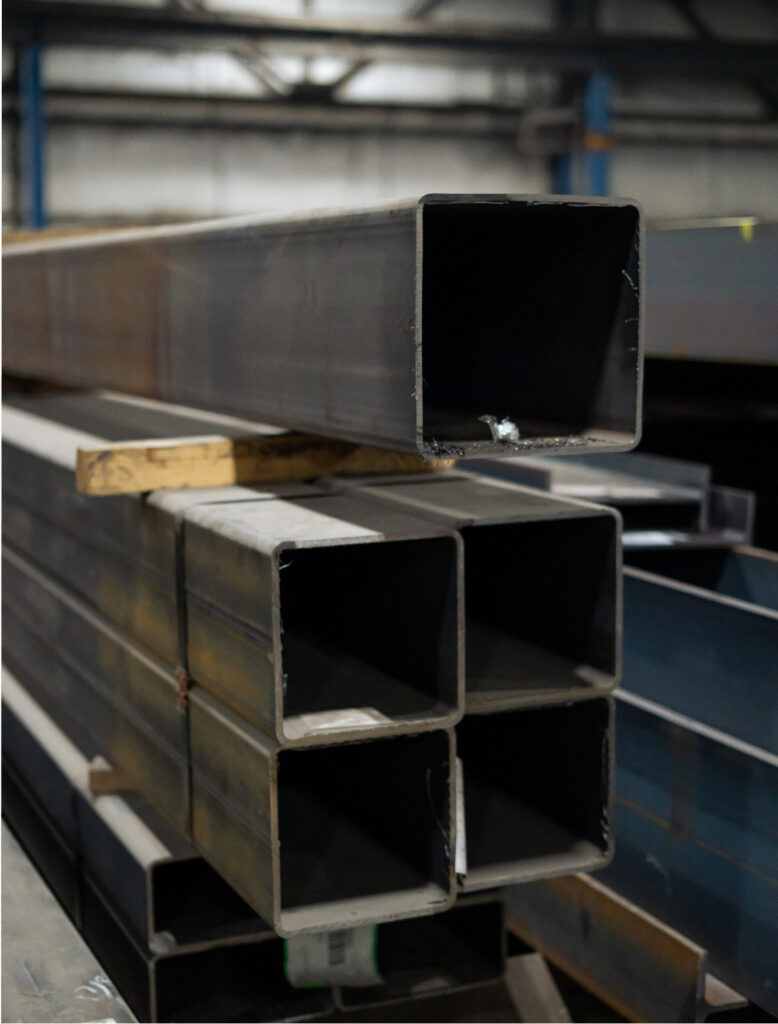

Complex Steel

Complexity energizes us. The more challenging the design, the greater the opportunity—and we embrace it. Whether it’s pipe columns, tube columns, or built-up channels, we specialize in handling steel of all shapes and sizes.

Our focus on precision, custom fabrication, and quality ensures every component fits seamlessly and performs as expected, no matter the complexity.

Miscellaneous Steel

Miscellaneous steel plays a key role in both a building’s function and design. We uniquely offer a comprehensive steel package, providing essential components such as:

- Roof Frames

- Roof Ladders

- Stairs

- Handrails

- Dock Stairs

- Girts

- Elevator Divider Beams

- Platforms

- Other Light Structural Steel

Turning Raw Steel into Real Solutions

What is Steel Fabrication?

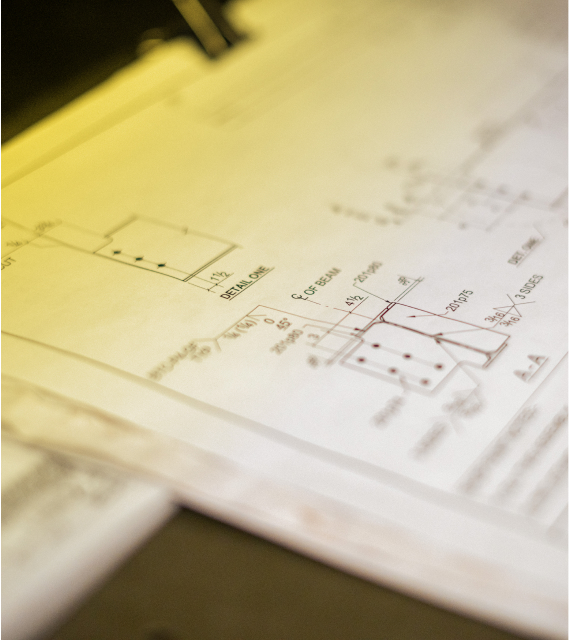

Detailing the Designs

Sourcing the Material

Processing

Using state of the art CNC technology, raw steel is cut, formed, and drilled to tolerance for the exact needs of the structure.

Welding and Assembly

Certified welders fit and weld connection material to the main members to form a stable structure that meets the intent of the design.

Painting and Finishing

We blast the steel to an SP10 finish, meeting the coating needs of your building to ensure high performance and aesthetics for years to come.

Safety and Quality

Dedicated safety and certified quality inspectors execute rigorous programs to ensure the structure is fabricated safely to AISC and project specifications.

Delivery and Install

The Lenex fleet executes a smooth delivery and experienced project managers oversee installation—ensuring not one detail is overlooked.